Have you ever wondered how your industrial facility or building manages to keep cool, even during intense summer heatwaves? Choosing the right cooling solution can be confusing, especially when you’re considering cooling towers and chillers. Both are commonly used for heat removal, but knowing the difference can help you significantly reduce costs and improve efficiency.

Cooling towers remove heat using evaporative cooling, making them ideal for large-scale industrial applications, while chillers use refrigeration cycles suitable for precise temperature control in smaller or specialized settings.

To help you make the best choice, let’s dive deeper into understanding how these two cooling systems operate and differ from each other.

What are Cooling Towers and Chillers?

Cooling towers and chillers are essential components in HVAC and industrial cooling systems, each designed to remove heat but with different methods and suitable applications.

Cooling Towers:

Cooling towers function by evaporative cooling, where hot water from your system sprays over a surface, and as air passes over it, the water evaporates, thereby cooling the remaining water. This cooled water recirculates back through your facility to absorb more heat.

Advantages:

- Energy-efficient for large-scale applications

- Cost-effective due to low energy consumption

Disadvantages:

- Requires continuous water supply

- Regular maintenance to prevent scaling and biological growth

- Efficiency dependent on weather conditions

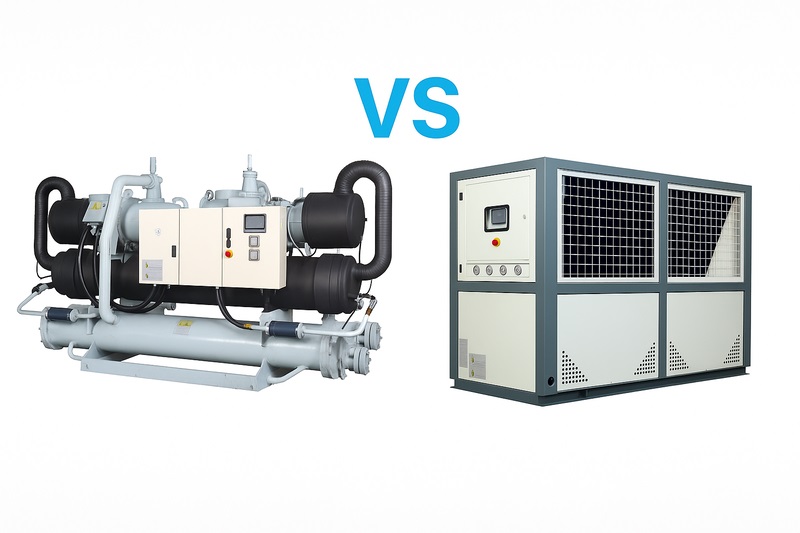

Chillers:

Chillers, on the other hand, remove heat using refrigeration cycles, transferring heat from a liquid (usually water) to a refrigerant. The chilled water circulates to cool air or equipment directly.

Advantages:

- Precise temperature control

- Does not require a constant water supply

- Effective regardless of weather conditions

Disadvantages:

- Higher energy consumption

- Higher initial investment

- Regular maintenance required, especially refrigeration components

Quick Comparison Table:

| Feature | Cooling Towers | Chillers |

|---|---|---|

| Method | Evaporative cooling | Refrigeration cycle |

| Energy Consumption | Lower | Higher |

| Initial Cost | Lower | Higher |

| Water Usage | Continuous requirement | Minimal |

| Ideal Application | Large industrial & HVAC systems | Smaller, precise cooling needs |

| Climate Dependence | High | Low |

To deepen your understanding, visit Wikipedia.org for comprehensive cooling tower information and Wikipedia for chiller system guidelines.

How Do Cooling Towers Work with Chillers?

As a professional with decades of experience in industrial cooling solutions at IceStar Energy, I often explain to clients how cooling towers and chillers work together to enhance efficiency.

Cooling towers and chillers integrate by allowing chillers to precisely cool water, which absorbs heat and then transfers it to cooling towers for efficient heat rejection via evaporative cooling.

The detailed process involves the chiller cooling water using a refrigerant. This chilled water circulates through your building or equipment, collecting heat. After absorbing heat, the warmed water moves to the cooling tower. Here, the evaporative cooling process reduces the water temperature significantly. Finally, this cooled water returns to the chiller, restarting the cycle.

This partnership significantly boosts energy efficiency and reduces operational costs, making it ideal for hospitals, manufacturing facilities, and data centers.

Can a Chiller Work Without a Cooling Tower?

Absolutely! Chillers don’t necessarily need cooling towers to operate, especially in certain situations.

Yes, chillers can function without cooling towers using alternatives like air-cooled chillers or closed-loop cooling systems, ideal for water conservation and smaller installations.

Air-cooled chillers are perfect for locations with limited water access because they use ambient air to dissipate heat, eliminating the need for continuous water supply. Alternatively, closed-loop systems can transfer heat to an external heat exchanger, avoiding cooling towers entirely. This versatility allows for precise cooling control in water-scarce environments, saving significant operational and maintenance costs.

Do Air-Cooled Chillers Use Cooling Towers?

No, air-cooled chillers don’t use cooling towers, making them highly beneficial in certain scenarios.

Air-cooled chillers dissipate heat directly into the atmosphere using fans blowing air over condenser coils, thus eliminating the need for cooling towers entirely.

This approach simplifies your system design, reduces water consumption drastically, and significantly cuts down on maintenance efforts. If your facility has limited water availability or space constraints, air-cooled chillers offer a practical and efficient solution.

Conclusion

Understanding the differences and complementary functions of cooling towers and chillers ensures you choose the optimal cooling solution for your facility. Cooling towers are ideal for large-scale, energy-efficient applications, while chillers provide precision cooling for smaller or specific needs.

At IceStar Energy Technology, we specialize in customized industrial refrigeration solutions tailored to your unique requirements. Our expertise ensures your operations remain energy-efficient, cost-effective, and reliably cool year-round. For more insights or personalized assistance, contact us today.