Industrial chillers ensure precise temperature control in petrochemical processes, enhancing operational efficiency, equipment longevity, and product quality.

Precision cooling solutions ensure optimal temperature control in food and beverage processing, preserving product quality, enhancing safety, and maximizing operational efficiency.

Precise temperature control ensures optimal reaction conditions, enhancing product quality and process efficiency.

Water-cooled and air-cooled systems enables precise thermal management, ensuring accurate and reliable testing conditions for your critical applications.

For plastic processing equipment like injection molding and blow molding machines, a Plastic Chiller efficiently removes excess heat.

Ensuring precise air conditioning or liquid cooling is crucial for the optimal performance of chip manufacturing and semiconductor processes.

Precision-engineered thermal control solutions optimize heat dissipation in printing and dyeing processes, ensuring consistent color quality, enhanced efficiency, and extended equipment lifespan.

Harnessing advanced thermal exchange technology, our solutions optimize climate control in commercial real estate, enhancing energy efficiency, sustainability, and operational cost savings.

Engineered for precision thermal management, our advanced cooling solutions optimize HVAC efficiency in construction projects, ensuring sustainable climate control and peak operational performance.

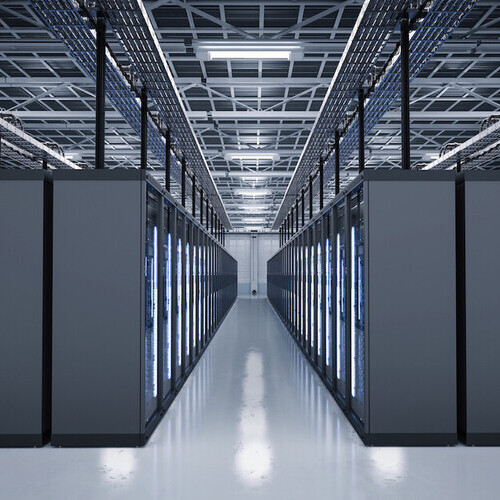

Enhancing thermal management in data centers, our advanced cooling systems optimize heat dissipation, ensuring operational stability, energy efficiency, and infrastructure longevity.

Precision thermal management solutions ensure optimal temperature control in lithium-ion battery manufacturing, enhancing efficiency, prolonging equipment lifespan, and safeguarding product integrity.

Harnessing advanced thermal management, our solutions ensure precise temperature control in biological fermentation, optimizing microbial activity and maximizing yield efficiency.

Our industrial chillers are tailored to optimize your operations, providing reliable and efficient cooling solutions that align with the specific demands of your industry.

Each chiller is crafted with meticulous attention to detail and subjected to comprehensive testing, guaranteeing superior performance and reliability.

Our chillers comply with international environmental standards while delivering high efficiency at a more affordable cost, making sustainable cooling solutions accessible to more businesses.

Custom-designed solutions with turnkey installation, 24/7 technical support, and fast spare parts delivery ensure seamless integration, minimal downtime, and comprehensive service from consultation to after-sales support.

With an annual production capacity of 20,000+ units, advanced automated assembly lines, and rigorous quality control, we ensure precision, efficiency, and reliable performance for global demand.

Our R&D team consists of over 100 engineers and experts, continuously advancing energy-efficient cooling technologies to meet the diverse needs of various industries.

We deliver high-performance chillers comparable to top global brands at a more competitive price. With fast customization and reduced lead times, we help lower your costs while meeting your specific needs efficiently.

We design tailored chillers to meet specific needs, from ultra-low temperatures to high-efficiency and harsh environments. Our agile approach ensures faster adaptation to unique applications and emerging market demands compared to global brands.

IceStar is a well-established brand with over 20 years of experience in the chiller manufacturing industry. Unlike new brands, we have built a solid reputation globally for providing high-quality air-cooled and water-cooled chillers. Our products are trusted by clients in over 68 countries and across various industries. We focus on delivering efficient and reliable cooling solutions backed by our strong R&D capabilities and dedicated team.

Yes, IceStar offers both OEM and ODM services to meet the specific needs of our clients. Whether you need custom-designed chillers or products tailored to your unique specifications, our experienced team can provide solutions that align with your requirements. We ensure top quality and efficiency, whether it's for a large-scale project or smaller, customized orders.

To select the right chiller size for your application, consider the following steps:

Determine Cooling Capacity: Calculate the cooling load required for your process, which depends on factors like heat generation, flow rate, and temperature difference.

Type of Fluid: Consider whether you're cooling water, air, or another fluid, as this affects the chiller specifications.

Operating Conditions: Take into account the ambient temperature, the required temperature of the chilled medium, and the specific conditions of your environment.

Chiller Efficiency: Choose a chiller that balances energy efficiency with cooling capacity to ensure optimal performance and lower operating costs.

Future Expansion: Consider any future increases in cooling demand and opt for a system that can accommodate growth.

Consult with Experts: If you're unsure, it's always best to consult with a professional to help you select the best chiller for your specific application.

When choosing between an air-cooled chiller and a water-cooled chiller, consider the following factors:

Installation Space:

Efficiency:

Environmental Conditions:

Maintenance:

Initial Cost:

In conclusion, if space, lower initial cost, and simplicity are important to you, an air-cooled chiller may be the better choice. However, if you need higher efficiency and are working with larger systems, a water-cooled chiller could be more suitable.

IceStar offers a wide range of chiller products, including:

Water-Cooled Chillers: Ideal for applications requiring high cooling efficiency with lower environmental impact.

Air-Cooled Chillers: Best suited for environments with limited water availability, offering easy installation and maintenance.

Evaporative Screw Chillers: A highly efficient option combining the best features of air and water cooling systems.

Low-Temperature Chillers: Designed for processes requiring subzero temperatures, ensuring precise cooling control.

Centrifugal Chillers: High-capacity chillers, perfect for large-scale industrial applications with significant cooling demands.

Each of these products comes in various capacities to meet different industrial and commercial needs.

Industry Expertise: With over 20 years of experience, IceStar has developed a strong reputation for reliable and high-performance chiller systems.

Customized Solutions: We offer tailored chiller systems that meet the unique needs of different industries, ensuring optimal efficiency and performance.

High-Quality Manufacturing: Our state-of-the-art production facility and rigorous quality control processes guarantee the durability and reliability of every unit.

Energy Efficiency: We focus on developing energy-saving chillers that reduce operating costs and support environmentally friendly solutions.

Global Reach: IceStar has successfully delivered chillers to over 68 countries, with a diverse portfolio of satisfied customers across industries like food processing, chemicals, and lithium extraction.

Comprehensive Support: We provide full project support, from product selection to after-sales service, ensuring our clients have a smooth experience throughout the product lifecycle.

To become an agent or distributor for IceStar in your country, simply reach out to us through our website or contact our sales team directly. We will provide you with all the necessary information regarding partnership opportunities, including the benefits, requirements, and terms for becoming an authorized distributor. We look forward to collaborating with you and expanding our reach together.

The main differences between industrial and commercial chillers are:

Application: Industrial chillers are designed for large-scale operations, such as manufacturing plants, chemical processing, and heavy-duty cooling systems. They handle higher capacities and more demanding cooling requirements. Commercial chillers, on the other hand, are typically used in smaller settings like offices, retail stores, or restaurants, where the cooling demands are less intensive.

Capacity: Industrial chillers generally have much higher cooling capacities (ranging from 20 to 500 tons or more), while commercial chillers are usually smaller, with capacities ranging from 1 to 20 tons.

Durability and Design: Industrial chillers are built for continuous operation in harsh environments, offering enhanced durability and efficiency. Commercial chillers are designed for shorter usage periods and less rigorous conditions.

Cost: Industrial chillers are more expensive due to their advanced features, larger size, and robust design. Commercial chillers are relatively more affordable as they serve smaller-scale applications.

Customization: Industrial chillers often require more customization based on the specific needs of a factory or industrial process, while commercial chillers have more standard configurations suited for general commercial use.

The type of coolant or liquid you should use for your chiller depends on several factors:

Water: For most general cooling applications, water is commonly used due to its excellent thermal conductivity and availability. It’s ideal for systems operating at moderate temperatures.

Glycol Mixtures: If your application requires operation in freezing or sub-zero conditions, a water-glycol mix (usually ethylene or propylene glycol) is recommended. This helps prevent freezing and ensures proper flow at low temperatures.

Specialized Coolants: For certain high-performance or specialized industrial applications, you might require custom coolants designed for specific temperature ranges or chemicals.

Compatibility: Always ensure that the coolant is compatible with your chiller's materials and seals to avoid damage and ensure efficient operation.

Environmental Considerations: Choose a coolant with low environmental impact, especially if leakage or spills are a concern. Non-toxic and biodegradable coolants are preferred in many industries.

It's best to consult with your chiller manufacturer or a cooling system expert to ensure the correct coolant is selected for your specific needs.

IceStar offers a wide range of chillers with cooling capacities from 0.5 Tons to 500 Tons, featuring adjustable temperature settings ranging from -35℃ to +35℃. This flexibility ensures that we can provide the ideal solution for various industrial applications.

Once we receive your chiller inquiry, our team will get back to you within 24 hours via email or phone. We take into account all the specific requirements you provide and ask a few additional questions to ensure we customize the chiller to your needs.

Typical questions include details about the installation environment, required cooling capacity, size specifications, and the intended application.

Through effective communication, the IceStar team ensures you receive the best guidance to choose the ideal chiller system for your project.

Once we have gathered all the details from your inquiry via email or phone, we review your specific requirements and forward them to our expert engineers. They then assess the manufacturing costs based on the application needs and provide a tailored solution.

Once the design and cost estimates are finalized by our engineering team, we will send you a detailed quotation. This will include a comprehensive review of the chiller specifications, cost, cooling capacity, size, and more. The quote will help you make an informed decision by comparing the cost and other essential factors.

Our engineering team is dedicated to offering the best possible solution tailored to your chiller needs.

Once you review the quote or other solutions provided by our team, you may have questions regarding discounts, delivery time adjustments, or other terms. We are happy to address all your concerns and work towards a mutually beneficial agreement.

After resolving any queries, we finalize the deal and await your confirmation to proceed with the order.

Once the deal is confirmed and we receive your order, our manufacturing team begins by sourcing the required components, such as compressors, evaporators, condensers, and more, based on your specific needs.

After all materials are gathered, our engineers start the production process, ensuring every stage is carefully monitored to maintain the highest quality standards. We prioritize using reliable, high-quality materials that best suit your order.

Once manufacturing is complete, the chiller undergoes rigorous testing in our Quality Control department to ensure it meets all specifications and performance requirements.

Throughout the production process, we keep you informed about the manufacturing timeline and estimated delivery date. Once the final testing is completed, the chiller is securely packed in wooden crates to ensure safe transportation.

As per our agreement, we will deliver the chiller to your specified location via sea or air. You will also receive all necessary shipping documents to facilitate the smooth arrival and claiming of your chiller.

Along with your chiller delivery, we provide all essential documentation, including a hard copy of the installation instructions. Please review these carefully to ensure proper installation.

If you prefer a digital version, feel free to request it, and we will send it to you via email.

Should you encounter any issues during installation or operation, our technical team is available to assist you at any time, offering expert support and guidance to ensure smooth operation.

IceStar offers a 24-month warranty on all chillers. If you encounter any issues during this period, simply contact us, and we will replace faulty components with spare parts and provide free technical support.

If your chiller is running smoothly and you're satisfied with our products, feel free to reach out to our sales team for any re-order requests. We’ll be happy to assist you with your next purchase.

info@icestartec.com