When it’s time to replace your old chiller, the pressure is on to choose something that balances budget, efficiency, and reliability. As someone who’s worked with industrial refrigeration systems for over 20 years, I understand what you’re up against. You need something that installs smoothly, runs efficiently, and doesn’t blow your budget — all while keeping your operation cool and uninterrupted.

Air-cooled chillers are often the ideal solution for replacement projects due to their simple installation, low initial cost, and minimal maintenance.

In this article, I’ll walk you through the advantages, limitations, and selection tips for air-cooled chillers. You’ll also get expert insights on how to choose between scroll and screw compressors — and what kind of lifespan to expect.

Let’s explore how to make your next replacement project more affordable and efficient — without sacrificing performance.

Why Choose Air-Cooled Chillers for Replacement Projects?

When we talk about retrofitting or replacing existing chiller systems, the conversation often starts with one major question: what’s the easiest, fastest, and most cost-effective system to install?

Air-cooled chillers win the race for replacement projects thanks to their compact design, low maintenance, and simplified installation process.

Here’s what we’ve seen on-site:

✅ Key Benefits of Air-Cooled Chillers in Replacement Projects

| Feature | Benefit |

|---|---|

| No Cooling Towers | Eliminates need for additional infrastructure |

| Lower Installation Costs | No water loops or pumps required |

| Compact Design | Ideal for tight mechanical rooms and rooftops |

| Fewer Maintenance Needs | No water treatment, lower corrosion risk |

| Modern Efficiency | Advanced models offer up to 60% IPLV improvement |

These benefits make air-cooled chillers the go-to for mid-sized industrial buildings, labs, and factories — especially where time and cost constraints matter.

To keep reading, let’s explore some critical questions you may have — including equipment lifespan, disadvantages, and choosing the right compressor technology.

What is the Life Expectancy of an Air-Cooled Chiller?

If you’re planning an upgrade, you’re likely wondering: how long will this new chiller last?

With proper maintenance, air-cooled chillers typically last between 15 to 20 years.

Of course, several factors affect longevity:

🔍 Key Determinants of Lifespan

- Maintenance: Regular cleaning of condenser coils, checking refrigerant levels, and predictive servicing can significantly extend lifespan.

- Operating Conditions: High ambient temperatures and sustained loads wear systems faster.

- Compressor Type: Screw compressors generally last longer than scroll types under heavy-duty use.

By investing in predictive maintenance and upgrading to chillers with digital control systems (e.g., DDC, VFDs), many clients have seen their systems last well over 18 years with minimal downtime.

Still, we recommend evaluating ROI after 15 years — energy efficiency and refrigerant regulations evolve quickly.

What are the Disadvantages of Air-Cooled Chillers?

No technology is perfect — and yes, air-cooled chillers come with trade-offs.

The main disadvantages include lower energy efficiency, noise, and reduced scalability for large-scale applications.

Let’s break that down:

⚠️ Common Drawbacks

- Efficiency Drop in High Heat: Performance dips when ambient temps exceed 35°C (95°F).

- Noise: Large condenser fans generate more noise than water-cooled systems.

- Space Requirements: Requires 6–10 ft of clearance for proper airflow.

- Higher Long-Term Energy Costs: Although maintenance is lower, electricity use may be higher.

🛠️ Mitigation Strategies

| Issue | Solution |

| High Ambient Temps | Use evaporative pre-cooling or VFD-equipped models |

| Noise | Install acoustic barriers or rooftop isolation |

| Energy Costs | Choose systems with high IPLV and part-load efficiency |

For operations running 24/7 or in extremely hot climates, a water-cooled option might make more sense. But for most replacement projects, the pros still outweigh the cons.

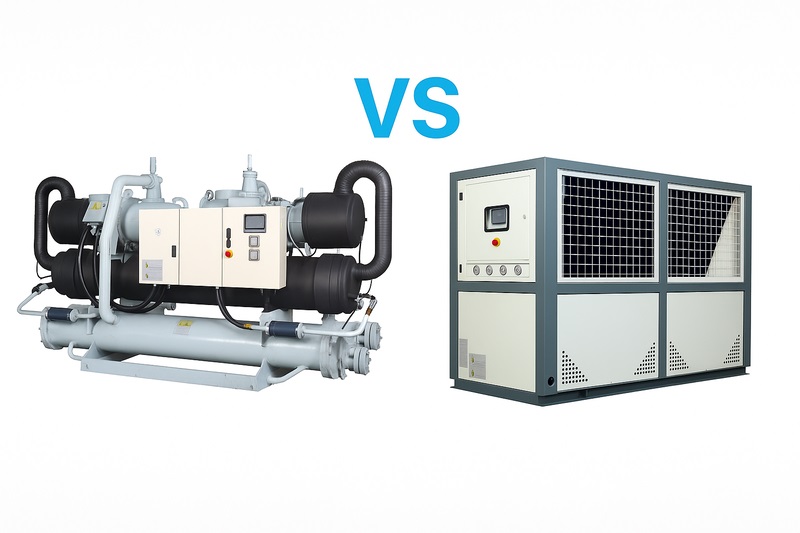

Which Is Better: Screw or Scroll Chiller?

Choosing between screw and scroll chillers depends on your cooling load, budget, and performance expectations.

Screw chillers are ideal for high-capacity, continuous-use applications. Scroll chillers suit smaller, budget-conscious projects with intermittent loads.

Here’s a quick comparison:

| Feature | Scroll Chiller | Screw Chiller |

| Capacity | 10–150 tons | 30–500+ tons |

| Noise | Quieter | Louder |

| Cost | Lower | Higher |

| Maintenance | Lower (fewer moving parts) | Higher (serviceable but complex) |

| Efficiency | Great part-load | Great full-load |

| Best for | Offices, labs | Industrial plants |

When clients ask me which to choose, I always ask about the workload pattern. If your facility runs continuously, screw chillers offer durability and flexibility. But for typical replacements in commercial or light industrial environments, scroll chillers hit the sweet spot of cost and performance.

Final Thoughts: Plan Smart, Save More

Every replacement project is a chance to upgrade more than just equipment — it’s an opportunity to increase reliability, cut costs, and reduce maintenance headaches.

At IceStar, we help clients design and deliver air-cooled chiller solutions tailored to their replacement needs. Whether you’re dealing with tight spaces, rising energy bills, or aging systems, we’ll help you find a solution that pays off in performance and peace of mind.

Still deciding which chiller is right for you? Don’t guess — reach out. We’d love to help you evaluate your site and choose the most affordable, effective system for your future.