Experience next-level energy efficiency, stability, and cooling capacity with IceStar’s industrial-grade centrifugal chillers tailored for your most demanding applications.

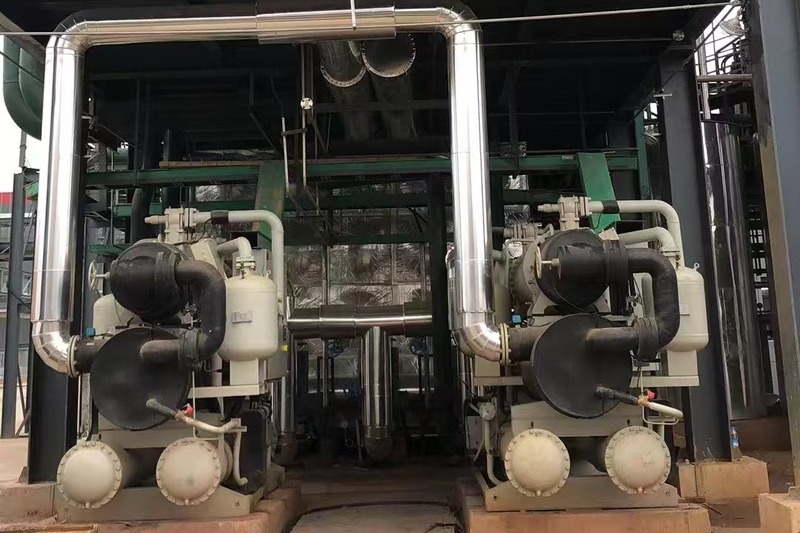

Centrifugal chillers are large-scale refrigeration systems designed for central cooling of buildings and industrial processes. Using centrifugal force to compress refrigerants, these chillers are known for their exceptional efficiency, low maintenance requirements, and ability to handle high cooling loads. IceStar’s centrifugal chillers deliver precise temperature control, reduced energy costs, and long-lasting performance for critical cooling environments.

Centrifugal chillers are the preferred choice for industrial and commercial cooling due to their:

IceStar centrifugal chillers are trusted across a wide range of sectors:

At IceStar, we don’t just manufacture equipment—we deliver confidence. With over 20 years of experience, we combine industry expertise, engineering excellence, and end-to-end support to bring our clients smart cooling solutions that reduce costs, enhance energy efficiency, and improve operational stability.

We are a long-term partner of top global brands like CATL, BYD, and 3M because we prioritize performance, reliability, and customer satisfaction. When you choose IceStar, you’re choosing a brand backed by proven results, innovative R&D, and a commitment to environmental responsibility.

Our state-of-the-art 36,000㎡ facility integrates R&D, machining, assembly, and testing in one streamlined operation. Every chiller undergoes strict quality control and performance testing before shipment. We utilize advanced production technologies and precision tools to ensure each unit meets international standards for reliability, efficiency, and safety. IceStar’s manufacturing process is guided by ISO certifications and lean production principles to ensure timely delivery and consistent quality.

With an annual production capacity of over 6,000 units, IceStar has a dedicated team of more than 100 professionals specializing in R&D, manufacturing, and quality control.

To ensure the best chiller solution, consider the following:

Once we receive your chiller inquiry, our team will get back to you within 24 hours via email or phone. We take into account all the specific requirements you provide and ask a few additional questions to ensure we customize the chiller to your needs.

Typical questions include details about the installation environment, required cooling capacity, size specifications, and the intended application.

Through effective communication, the IceStar team ensures you receive the best guidance to choose the ideal chiller system for your project.

Once we have gathered all the details from your inquiry via email or phone, we review your specific requirements and forward them to our expert engineers. They then assess the manufacturing costs based on the application needs and provide a tailored solution.

Once the design and cost estimates are finalized by our engineering team, we will send you a detailed quotation. This will include a comprehensive review of the chiller specifications, cost, cooling capacity, size, and more. The quote will help you make an informed decision by comparing the cost and other essential factors.

Our engineering team is dedicated to offering the best possible solution tailored to your chiller needs.

Once you review the quote or other solutions provided by our team, you may have questions regarding discounts, delivery time adjustments, or other terms. We are happy to address all your concerns and work towards a mutually beneficial agreement.

After resolving any queries, we finalize the deal and await your confirmation to proceed with the order.

Once the deal is confirmed and we receive your order, our manufacturing team begins by sourcing the required components, such as compressors, evaporators, condensers, and more, based on your specific needs.

After all materials are gathered, our engineers start the production process, ensuring every stage is carefully monitored to maintain the highest quality standards. We prioritize using reliable, high-quality materials that best suit your order.

Once manufacturing is complete, the chiller undergoes rigorous testing in our Quality Control department to ensure it meets all specifications and performance requirements.

Throughout the production process, we keep you informed about the manufacturing timeline and estimated delivery date. Once the final testing is completed, the chiller is securely packed in wooden crates to ensure safe transportation.

As per our agreement, we will deliver the chiller to your specified location via sea or air. You will also receive all necessary shipping documents to facilitate the smooth arrival and claiming of your chiller.

Along with your chiller delivery, we provide all essential documentation, including a hard copy of the installation instructions. Please review these carefully to ensure proper installation.

If you prefer a digital version, feel free to request it, and we will send it to you via email.

Should you encounter any issues during installation or operation, our technical team is available to assist you at any time, offering expert support and guidance to ensure smooth operation.

IceStar offers a 24-month warranty on all chillers. If you encounter any issues during this period, simply contact us, and we will replace faulty components with spare parts and provide free technical support.

If your chiller is running smoothly and you're satisfied with our products, feel free to reach out to our sales team for any re-order requests. We’ll be happy to assist you with your next purchase.

info@icestartec.com