Welcome to our in-depth discussion on a topic that many of you have been curious about. I am an industry expert with over 20 years of experience in industrial refrigeration. At IceStar Energy Technology Co., Ltd, we have dedicated our careers to providing innovative cooling and heat exchange solutions. Many companies struggle with the high costs and inefficiencies of managing separate systems for cooling and heating. This challenge affects your operations, your energy bills, and ultimately your bottom line.

Yes, chillers can be used for both cooling and heating purposes if they are equipped with advanced heat recovery or heat pump technology. This dual-function approach reduces energy waste, lowers operating costs, and simplifies system management. By using chillers that serve both functions, we help you optimize energy use and streamline your facility’s design.

In this article, I will share my personal insights and professional experience to explain how chillers work in dual roles. I will break down the technology behind heat recovery chillers and heat pump chillers, discuss their applications, and explain when a cooling tower is needed. We will also explore the benefits of a dual chiller system. I invite you to read on and discover valuable information that can help you make informed decisions for your facility.

Can Chillers Be Used for Both Cooling and Heating Purposes?

When you ask, “Can chillers be used for both cooling and heating purposes?” I understand your need for efficiency and cost savings. I have seen many businesses struggle with having separate systems that drive up energy consumption. In my professional journey at IceStar, I have witnessed how using the right technology can solve this problem.

Yes, chillers can be used for both cooling and heating purposes because they integrate heat recovery or heat pump technology. This dual functionality makes them very efficient and cost-effective. For instance, heat recovery chillers capture waste heat from the cooling cycle. They then use this heat to provide space heating or to produce hot water. Similarly, heat pump chillers reverse the refrigeration cycle. This reversal means they can switch between cooling and heating modes as needed. These systems are very adaptable and help you save on energy bills while lowering maintenance costs. For more neutral and detailed information, you might want to review the Wikipedia page on chillers.

Moreover, using these dual-purpose chillers makes your operation more sustainable. You reduce energy consumption and minimize environmental impact. The integration of cooling and heating in one unit simplifies your system design. It cuts down on installation costs and operational complexity. I have seen firsthand how businesses benefit from this innovative technology. It makes the entire facility easier to manage and more energy-efficient.

What Are the Water Chiller Applications?

Water chillers are essential in a variety of industries. They provide reliable temperature control and maintain process integrity. I have worked with clients in many sectors, from plastic manufacturing to healthcare, who rely on water chillers for consistent performance.

Water chillers are widely used in various industries such as plastic manufacturing, metalworking, food and beverage, chemical processing, and healthcare. They deliver efficient cooling regardless of the external temperature. This technology is not only versatile but also robust. It supports a wide range of applications, ensuring that your processes run smoothly. For further reading on how chillers work and their applications, please visit the Wikipedia page on industrial chillers.

Let me share a key points table that summarizes the main applications of water chillers:

| Application Area | Key Uses |

| Plastic Manufacturing | Cooling molds during injection and reducing cycle times |

| Metal and Machine Manufacturing | Maintaining precise temperatures to prevent distortion |

| Food & Beverage Processing | Ensuring product safety and quality through controlled cooling |

| Chemical & Pharmaceutical Production | Providing optimal process conditions to ensure reaction stability |

| Medical Facilities | Cooling sensitive equipment like MRI and X-ray machines |

| HVAC Systems | Used in large-scale air conditioning and district cooling systems |

| Data Centers | Preventing overheating of servers and IT equipment |

| Laboratories | Maintaining steady temperatures for experiments |

| Hydroponics | Regulating water temperatures for optimal plant growth |

I always encourage you to consider these applications when planning your facility’s cooling and heating needs. This understanding can guide you to make the right investment. It shows that water chillers are not just for one industry; they offer wide-ranging benefits that improve process control, product quality, and overall efficiency.

Does a Chiller Always Need a Cooling Tower?

This question is very common. Many customers ask whether a cooling tower is required for every chiller system. I have seen both setups in my years of experience, and each has its own merits.

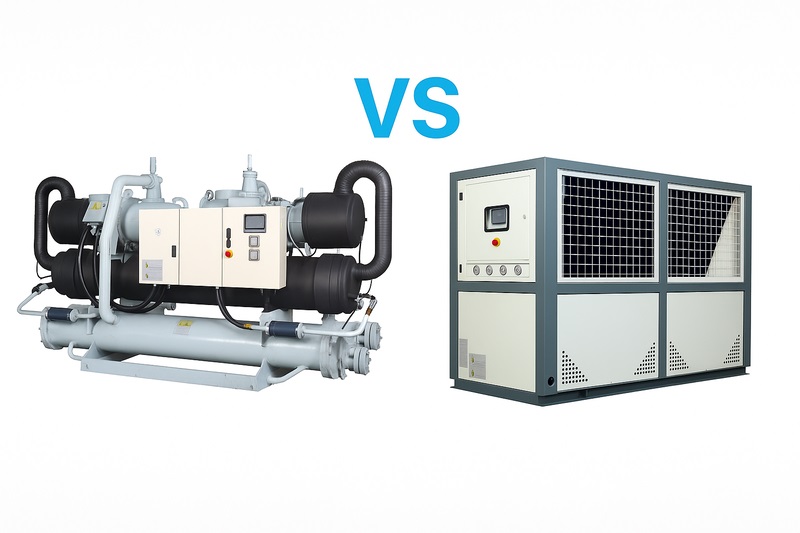

Chillers do not always need a cooling tower. Air-cooled chillers, for instance, dissipate heat directly into the ambient air and operate efficiently without additional components. However, water-cooled chillers usually pair with a cooling tower to reject heat effectively. The use of a cooling tower depends on your specific system design and the environmental conditions at your facility. For a neutral view on this topic, you can check the Wikipedia page on cooling towers.

To give you a clearer picture, here is a comparison table:

| Chiller Type | Requires Cooling Tower? | Advantages |

| Air-Cooled | No | Simple installation; minimal maintenance |

| Water-Cooled | Yes, typically | Higher efficiency; suitable for large-scale operations |

From my experience, if you operate in an area with abundant ambient air and lower humidity, an air-cooled chiller might be your best option. In contrast, water-cooled chillers, when paired with cooling towers, offer superior efficiency in high-demand environments. This setup is ideal if you have the space and water availability needed to support a cooling tower.

What Are the Benefits of Using a Dual Chiller System?

Now, let’s talk about dual chiller systems. In my years of working with various industrial clients, I have seen that dual systems often provide unmatched reliability and performance. They are a great choice for facilities that demand continuous and efficient operation.

A dual chiller system enhances reliability, flexibility, and efficiency. It provides redundancy so that if one chiller goes down, the other keeps your operations running smoothly. This setup reduces downtime and optimizes energy use. Dual systems also allow you to adjust cooling capacity to match your real-time demands. This flexibility ensures that you do not waste energy during off-peak times, which can lead to significant cost savings.

Here is a table summarizing the benefits of a dual chiller system:

| Benefit | Explanation |

| Enhanced Reliability | Redundant systems ensure continuous operation even during maintenance or failure of one unit. |

| Improved Efficiency | Dual systems can operate in parallel or series, optimizing energy use. |

| Flexibility | Ability to adjust cooling capacity based on real-time demand. |

| Cost Savings | Reduced energy consumption and lower maintenance costs over time. |

| Scalability | Easier to upgrade as cooling demands increase with facility expansion. |

I always advise my clients to consider dual chiller systems when planning large-scale or mission-critical operations. They offer peace of mind knowing that a backup is always ready. This arrangement also helps you manage peak loads more effectively, ensuring that your facility maintains optimal performance regardless of demand fluctuations.

Conclusion

In summary, chillers that are designed for both cooling and heating purposes offer a transformative solution for modern industrial and commercial facilities. Through my 20-plus years of experience, I have learned that the integration of heat recovery or heat pump technology in chillers not only simplifies your system design but also brings significant energy savings and cost benefits. By reducing the need for separate systems, you can streamline your operations and reduce environmental impact.

We discussed how water chillers are used across a wide range of industries, from plastic manufacturing to healthcare. We clarified that not every chiller requires a cooling tower; the choice depends on whether you opt for an air-cooled or water-cooled system. Finally, we examined the multiple benefits of using a dual chiller system, including enhanced reliability, improved efficiency, and operational flexibility.

As a professional in the industrial refrigeration field at IceStar Energy Technology Co., Ltd, I am proud to share these insights with you. I believe that understanding these key concepts can help you make informed decisions that save energy, reduce costs, and boost system performance. If you have further questions or need customized solutions, please feel free to reach out to us. We are here to support you in achieving the best outcomes for your facility.

Thank you for taking the time to read this article. I hope you now have a clearer understanding of how chillers can effectively serve both cooling and heating purposes. Remember, the right technology can transform your operations, reduce your expenses, and help you build a more sustainable future. We at IceStar are ready to help you tailor the perfect solution for your specific needs, ensuring you benefit from the latest innovations in industrial refrigeration and heat exchange.