When I talk with clients who are new to industrial cooling systems, I often hear the same confusion: “I understand what a chiller does… but how exactly does a cooling tower fit into the system?” If you’ve ever felt the same way, you’re not alone. Many engineers, plant managers, and energy supervisors struggle to visualize how these two pieces of equipment work together—especially when they’re under pressure to improve efficiency or solve persistent overheating problems.

The truth is simple: a cooling tower and a water-cooled chiller operate as one unified heat-rejection system. The chiller removes heat from your process or building water, and the cooling tower releases that collected heat to the outdoor air through evaporation. When both are designed and operated correctly, they deliver highly efficient, stable, and economical cooling—especially for large industrial applications.

And because my team at IceStar Energy Technology Co., Ltd. has spent more than 20 years designing these systems for petrochemical plants, lithium battery lines, plastics factories, breweries, and countless other industries, I want to break this relationship down in a way that’s practical, easy to digest, and directly useful for your real-world decisions.

How Do a Cooling Tower and Chiller Work Together?

When you look at the system from the outside, the components seem independent. But in actual operation, they’re deeply interconnected. Let me walk you through what really happens.

Understanding Their Basic Roles

If I simplify the system based on what I explain to my own customers:

- The chiller’s job: Create chilled water by absorbing heat from your building or process.

- The cooling tower’s job: Remove the chiller’s waste heat from the condenser water loop and reject it outdoors.

This relationship forms the beating heart of a water-cooled chiller plant.

A cooling tower and chiller work together by circulating two connected water loops: the chiller removes heat from the chilled-water loop, transfers it into the condenser-water loop, and the cooling tower then uses evaporation to expel that heat to the atmosphere before sending cooled water back to the chiller.

Two Interdependent Loops

To help you visualize it, here’s the simplest explanation I give during project meetings:

- Loop 1 — Chilled Water Loop:

The chiller cools water to about 6–7°C, sends it to your equipment or air handlers, and the water returns warmer (typically 12–13°C) after absorbing heat. - Loop 2 — Condenser Water Loop:

The cooling tower cools the water that removes heat from the chiller’s refrigerant.

Here is a table to make the interaction clearer:

| Part | Fluid It Handles | Heat Source | Heat Rejected To | Typical Location |

|---|---|---|---|---|

| Chiller evaporator | Chilled water | Building/process load | Refrigerant | Indoors |

| Chiller condenser | Condenser water | Refrigerant | Condenser-water loop | Indoors |

| Cooling tower | Condenser water | Chiller condenser | Outdoor air | Rooftop/outdoors |

What Happens in the Cooling Tower?

When the hot condenser water enters the cooling tower, it’s sprayed over fill material while air is drawn through by large fans. A small portion of the water evaporates—which pulls heat from the remaining water. That cooled water then collects in the tower basin and returns to the chiller.

The Whole Cycle Together

- Chiller evaporator removes heat from your building or process.

- Chiller condenser transfers heat into the condenser-water loop.

- Cooling tower rejects heat to outdoor air and recirculates cool water.

This cycle repeats continuously to keep your plant running safely and efficiently.

You might be thinking, “Okay, I get how they work—but do I really need both for my project?”

This is exactly the kind of question that leads companies to either overspend or under-design their cooling systems. So let me break it down based on what I’ve seen across thousands of installations.

Do You Need a Chiller with a Cooling Tower?

Different systems require different configurations, and selecting the right one can save you energy, capital cost, and long-term maintenance fees.

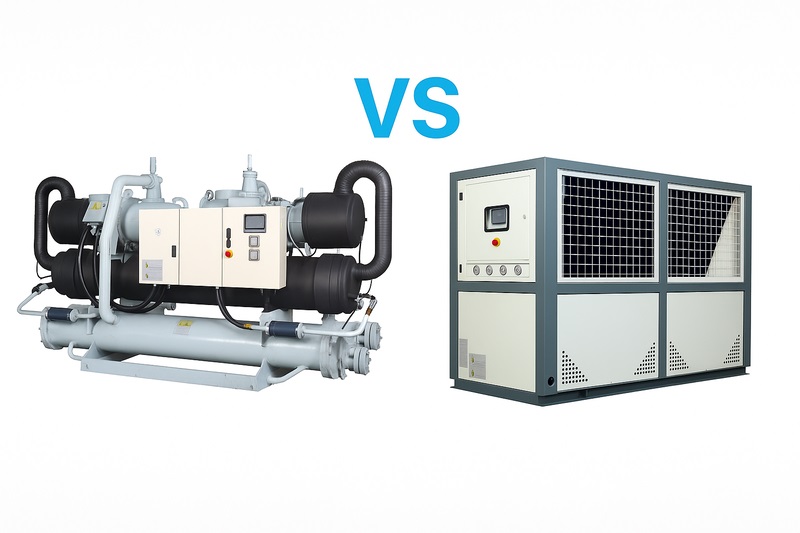

The honest answer—something I always share with clients—is that a cooling tower is not always necessary. It depends on your chiller type, cooling load, energy goals, and water availability.

You only need a cooling tower when you use a water-cooled chiller, because this type of chiller rejects heat into a condenser-water loop that must be cooled by an external device such as a cooling tower. Air-cooled chillers do not require cooling towers.

When You Do Need Both

Choose a chiller + cooling tower system if:

- Your cooling load is large or continuous

- Energy efficiency is a priority

- Water supply is reliable

- Long-term operating cost matters more than initial cost

Common installations include:

- Data centers

- Chemical plants

- Pharmaceutical factories

- Metallurgy and power facilities

- Breweries and food processing

- Large commercial buildings

When You Don’t Need a Tower

You do not need a cooling tower if:

- You are using an air-cooled chiller

- Water is limited or expensive

- You want a simpler system with less maintenance

How Do You Size a Cooling Tower for a Chiller?

Selecting the correct tower size is one of the most important decisions you’ll make. If you choose wrong, your chiller will never reach its rated capacity.

When I help customers choose the right tower, I always begin with this principle:

A cooling tower must handle the chiller’s total heat rejection—not just its cooling capacity.

A cooling tower is sized by calculating the chiller’s total heat rejection (cooling load + compressor heat), converting that load into “tower tons,” and selecting a tower rated to reject that heat at the site’s design wet-bulb temperature.

Key Sizing Concepts

Here’s what every engineer on your team should understand:

Cooling Capacity vs Heat Rejection

- 1 refrigeration ton = 12,000 Btu/h

- 1 cooling tower ton = 15,000 Btu/h (includes compressor heat)

Common Rule of Thumb

Tower Tons ≈ 1.25 × Chiller Tons

Example: 400-ton chiller → 500-ton cooling tower

Basic Calculation

Q = 500 × GPM × ΔT

(GPM = condenser-water flow, ΔT = tower range)

Typical Design Values

- Flow rate: ~3.0 gpm per ton

- Range: 10°F (95°F → 85°F)

- Approach: 5–10°F

Lower approach = larger tower + higher efficiency.

Practical vs Detailed Selection

- Concept design: Use 1.25 multiplier

- Final design: Use manufacturer selection software based on:

- Wet-bulb temperature

- Flow rate

- Range & approach

- Safety margin

Conclusion

Understanding how a cooling tower and chiller work together is more than theory—it affects your plant’s stability, energy cost, and long-term performance. When designed correctly, this pairing forms one of the most efficient cooling systems in the industrial world. At IceStar Energy Technology Co., Ltd, we’ve helped thousands of customers design, size, and optimize these systems for industries ranging from chemicals to food processing.

If you’re planning a new project or upgrading an existing plant, I’d be happy to help you evaluate whether you need a tower, how to size it, and how to optimize the entire cooling system for lowest lifecycle cost.