In today’s data-driven world, the way we cool data centers has become more than just a technical detail—it’s a critical business decision. As someone deeply involved in designing and delivering industrial cooling solutions at IceStar Energy Technology Co., Ltd., I’ve helped clients across various industries navigate this choice.

When it comes to cooling modern data centers—especially those supporting AI, high-performance computing (HPC), and high-density workloads—liquid cooling offers superior efficiency, lower operational costs, and better sustainability compared to traditional air cooling.

Still, many facilities stick with air cooling due to familiarity, lower upfront costs, and ease of implementation. So, how do you decide what’s right for your business? Let’s break it down and look at the pros, cons, and real-world suitability of each approach.

Liquid Cooling vs. Air Cooling: What’s the Difference?

The core difference lies in the medium used to dissipate heat—air or liquid. While the technology and implementation differ, the goal is the same: keep your IT equipment operating within optimal temperatures to avoid performance issues or failures.

Key Differences at a Glance

| Feature | Air Cooling | Liquid Cooling |

|---|---|---|

| Upfront Cost (CapEx) | Lower | Higher |

| Operating Expense (OpEx) | Higher | Lower |

| Energy Efficiency | Lower | Higher |

| Maintenance Complexity | Lower | Higher |

| High-Density Rack Support | Limited | Excellent |

| Carbon Footprint | Higher | Lower |

| Noise Level | Higher | Lower |

| Space Utilization | Less efficient | More efficient |

What Is Air Cooling and When Does It Work Best?

Air cooling is the most common solution in legacy and small-scale data centers. It uses fans and HVAC systems to move cool air through server racks and expel hot air.

Air cooling is cost-effective and easier to maintain, but struggles with high-density racks and growing energy bills.

Air cooling performs well in facilities with lower rack densities (typically below 15–20 kW/rack) and in environments where water access is limited or regulatory constraints make water use difficult.

However, air cooling can become inefficient as compute density and power consumption increase. It often demands significant infrastructure—such as raised floors, hot/cold aisle containment, and robust airflow management.

What Is Liquid Cooling and Why Is It Gaining Ground?

Liquid cooling is becoming the preferred choice for modern data centers focused on high-efficiency and sustainability. It delivers coolant directly to the source of heat—whether via direct-to-chip cooling, rear-door heat exchangers, or full immersion baths.

Liquid cooling is 3,000 times more effective at heat transfer than air, enabling support for dense, AI-driven computing workloads while cutting energy use significantly.

Liquid cooling excels in minimizing floor space, lowering power usage effectiveness (PUE), and maintaining quiet operations. It also opens up possibilities for heat reuse—such as warming office spaces or other industrial processes—making it a cornerstone in sustainable data center strategies.

Yet, it does come with a steeper learning curve and higher upfront investment. For retrofits, it can be complex to implement, and staff may need additional training.

Making the Right Choice: What Should You Consider?

The decision depends on your data center’s size, growth plans, budget, and sustainability goals. Here’s a quick comparison table:

| Situation | Recommended Cooling Method |

|---|---|

| Legacy or low-density data centers | Air Cooling |

| New builds with AI/HPC workloads | Liquid Cooling |

| Locations with limited water access | Air Cooling |

| Focus on energy efficiency & PUE | Liquid Cooling |

| Budget-constrained installations | Air Cooling |

| Dense server racks & limited space | Liquid Cooling |

What About the Chillers Behind the Cooling?

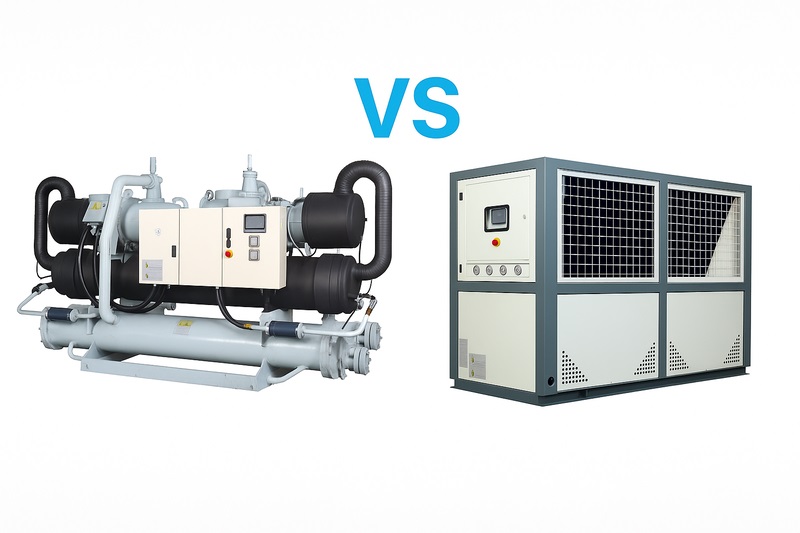

Let’s take it one step deeper. Behind both air and liquid cooling systems, you’ll typically find air-cooled or water-cooled chillers—the engines behind your thermal management.

If you’re wondering which is better for your setup, keep reading. I’ll break that down next.

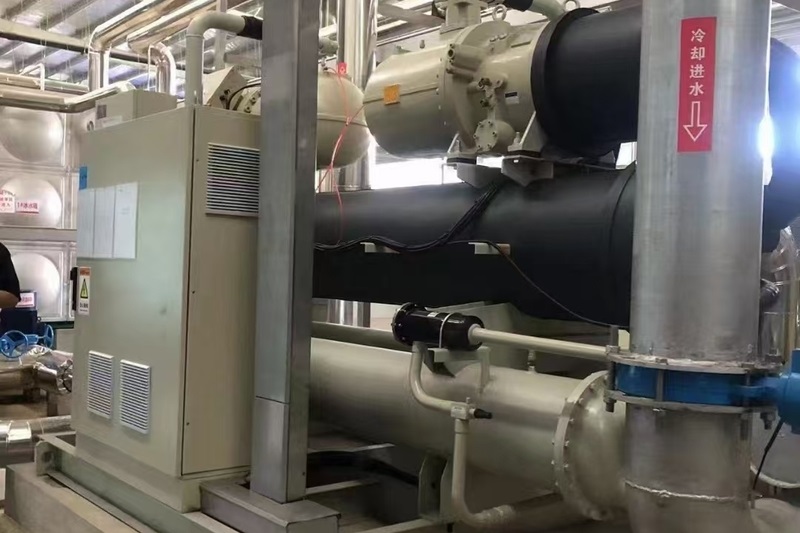

Why Water-Cooled Chillers Are Better Than Air-Cooled Chillers

Water-cooled chillers consistently outperform air-cooled systems in environments demanding high-efficiency and stable operation.

Water-cooled chillers deliver better energy efficiency, higher capacity, quieter operation, and longer equipment life—making them ideal for large-scale or high-density data centers.

Let me show you why many of our clients in data centers, industrial plants, and tech parks are shifting toward water-cooled solutions.

1. Energy Efficiency

Water-cooled chillers operate using cooling towers that rely on wet-bulb temperatures, which are significantly lower than the dry-bulb temperatures used in air-cooled systems. This allows compressors to run with less stress and at lower energy costs.

- Lower power usage = lower PUE.

- Stable performance in hot climates.

- Reduced operating expenses over time.

📚 Source: ASHRAE Technical Data Center Cooling Guidelines

2. Higher Cooling Capacity

Compared to air-cooled models, water-cooled systems support much larger loads. While air-cooled units max out around 500 tons, water-cooled chillers can exceed 4,000 tons.

This means:

- Better performance in high-density server environments.

- Elimination of “hot spots.”

- Consistent, uniform cooling across the rack floor.

3. Longer Service Life

Water-cooled chillers are typically installed indoors, protected from sun, rain, and debris. That alone can extend their life expectancy from 15–20 years (air-cooled) to 25–30 years.

- Less exposure to environmental wear.

- Fewer breakdowns and longer replacement cycles.

- Improved ROI in long-term projects.

4. Sustainability and Heat Recovery

Water-cooled systems not only reduce your electricity consumption but also offer the ability to repurpose waste heat—a major plus for ESG-conscious companies.

- Supports circular energy reuse.

- Lowers carbon emissions.

- Meets green building certifications (e.g., LEED, BREEAM).

When to Use an Air-Cooled Chiller

That said, air-cooled chillers still have a solid place in many applications—particularly when budgets are tight, installations are time-sensitive, or water access is an issue.

Air-cooled chillers are ideal for smaller-scale, portable, or rooftop installations where simplicity and cost control are key.

Let’s explore some use cases where air-cooled systems shine.

Ideal Scenarios:

| When to Use Air-Cooled Chillers | Why It Makes Sense |

|---|---|

| Remote or water-scarce locations | No need for water supply or cooling towers |

| Projects needing fast deployment | Easier to install, no water piping required |

| Tight budgets | Lower initial investment |

| Urban environments with space limits | Rooftop-ready, compact size |

| Mobile or modular facilities | Self-contained, portable |

| Low-to-moderate cooling loads | Sufficient capacity with simpler controls |

Final Thoughts: Matching Cooling Strategy to Data Center Goals

At IceStar Energy Technology, we believe there’s no one-size-fits-all solution. Instead, we help our partners evaluate their facility goals, performance targets, and growth forecasts to recommend the best system—whether that’s air, liquid, or a hybrid approach.

Liquid cooling is clearly the future of data center thermal management. But in many cases, air cooling and air-cooled chillers still offer a smart, cost-effective option.

When done right, the right cooling approach helps reduce energy costs, increase server uptime, and build a more sustainable IT footprint.

Looking to upgrade or design your cooling system? We’re here to help you choose smarter.