Reliable, energy-saving screw chiller solutions tailored for demanding industrial applications. Maximize cooling, minimize cost.

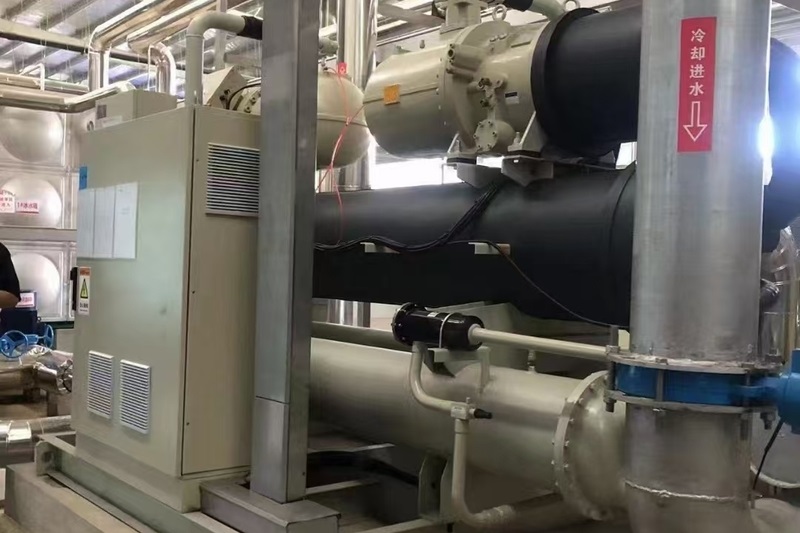

A screw chiller uses twin screw compressors to deliver continuous, high-capacity cooling for industrial systems. Known for their energy efficiency, low vibration, and quiet operation, screw chillers are ideal for applications that require stable performance and long-term reliability. IceStar offers both water-cooled and air-cooled screw chiller systems to meet various operational needs.

Screw chillers offer unmatched reliability and performance under heavy loads. Their semi-hermetic screw compressors provide smooth, continuous operation with minimal maintenance. Compared to other cooling systems, they are quieter, more energy-efficient, and better suited for year-round usage. Whether you need precise temperature control or stable operation in tough environments, screw chillers deliver.

✔ Energy Efficiency: Up to 30% reduction in energy use through advanced screw compressor technology.

✔ Stable Operation: Designed for continuous, 24/7 operation even in harsh climates.

✔ Smart Control: Real-time monitoring and remote access ensure easy and safe operation.

✔ Low Maintenance: Premium components reduce downtime and service costs.

✔ Compact Footprint: Flexible design fits into space-limited facilities.

✔ Environmentally Friendly: Eco-friendly refrigerants and sustainable systems reduce environmental impact.

IceStar screw chillers are trusted across multiple industries, including:

At IceStar, we don’t just manufacture chillers—we deliver results. Our screw chillers are engineered by a team of R&D specialists and produced in our 36,000㎡ cutting-edge facility. We emphasize long-term performance, energy savings, and operational stability.

More than just machines, our systems are part of your business success. IceStar is proud to be the trusted supplier for leading companies like CATL, Sinopec, and BYD. Our global reputation is built on real results, repeat clients, and a relentless focus on quality.

From concept to delivery, every IceStar screw chiller goes through a rigorous process:

With an annual production capacity of over 6,000 units, IceStar has a dedicated team of more than 100 professionals specializing in R&D, manufacturing, and quality control.

Before making an investment, evaluate the following:

Once we receive your chiller inquiry, our team will get back to you within 24 hours via email or phone. We take into account all the specific requirements you provide and ask a few additional questions to ensure we customize the chiller to your needs.

Typical questions include details about the installation environment, required cooling capacity, size specifications, and the intended application.

Through effective communication, the IceStar team ensures you receive the best guidance to choose the ideal chiller system for your project.

Once we have gathered all the details from your inquiry via email or phone, we review your specific requirements and forward them to our expert engineers. They then assess the manufacturing costs based on the application needs and provide a tailored solution.

Once the design and cost estimates are finalized by our engineering team, we will send you a detailed quotation. This will include a comprehensive review of the chiller specifications, cost, cooling capacity, size, and more. The quote will help you make an informed decision by comparing the cost and other essential factors.

Our engineering team is dedicated to offering the best possible solution tailored to your chiller needs.

Once you review the quote or other solutions provided by our team, you may have questions regarding discounts, delivery time adjustments, or other terms. We are happy to address all your concerns and work towards a mutually beneficial agreement.

After resolving any queries, we finalize the deal and await your confirmation to proceed with the order.

Once the deal is confirmed and we receive your order, our manufacturing team begins by sourcing the required components, such as compressors, evaporators, condensers, and more, based on your specific needs.

After all materials are gathered, our engineers start the production process, ensuring every stage is carefully monitored to maintain the highest quality standards. We prioritize using reliable, high-quality materials that best suit your order.

Once manufacturing is complete, the chiller undergoes rigorous testing in our Quality Control department to ensure it meets all specifications and performance requirements.

Throughout the production process, we keep you informed about the manufacturing timeline and estimated delivery date. Once the final testing is completed, the chiller is securely packed in wooden crates to ensure safe transportation.

As per our agreement, we will deliver the chiller to your specified location via sea or air. You will also receive all necessary shipping documents to facilitate the smooth arrival and claiming of your chiller.

Along with your chiller delivery, we provide all essential documentation, including a hard copy of the installation instructions. Please review these carefully to ensure proper installation.

If you prefer a digital version, feel free to request it, and we will send it to you via email.

Should you encounter any issues during installation or operation, our technical team is available to assist you at any time, offering expert support and guidance to ensure smooth operation.

IceStar offers a 24-month warranty on all chillers. If you encounter any issues during this period, simply contact us, and we will replace faulty components with spare parts and provide free technical support.

If your chiller is running smoothly and you're satisfied with our products, feel free to reach out to our sales team for any re-order requests. We’ll be happy to assist you with your next purchase.

info@icestartec.com